BENEFIT #1

BOTTLENECKS REMOVED

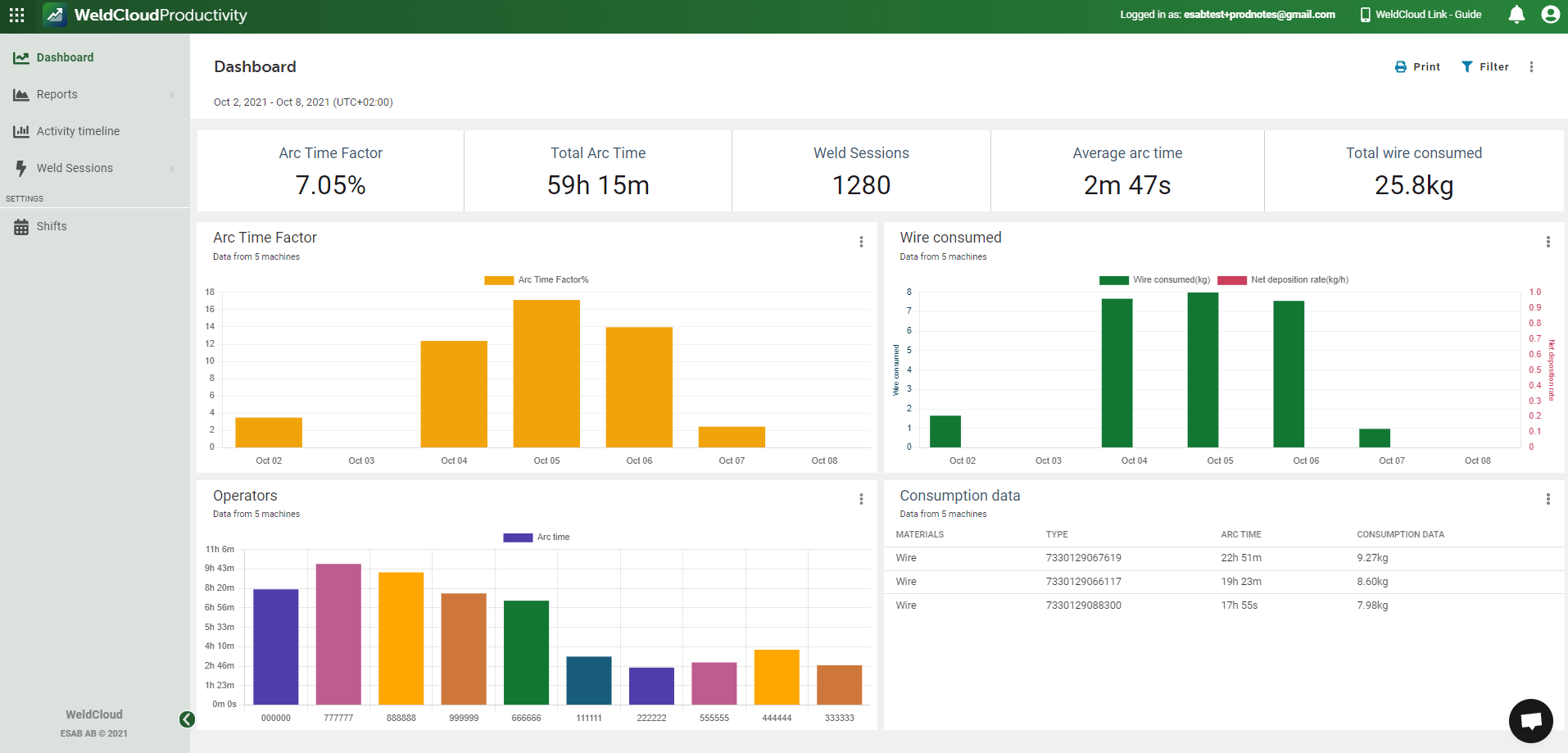

While technically an online application, WeldCloud Productivity has actually proven to be a communication tool between management and operators.

”The problem was lack of information coming to the management level. WeldCloud helped us figure out our production issues,” says Särkinen. “In retrospect, the causes were so mundane. Now the operators know we are there to work with them to solve problems.”

Common problems included lack of proper tools such as grinders or pneumatic needle scalers, waiting for cranes and inconsistent part fit-up.

BENEFIT #2

TRUE COSTS IDENTIFIED

Särkinen works closely with customer design and engineering teams to develop prototypes. Because these are large, complex and heavy components, fabrication costs are high. With WeldCloud, Särkinen can track and charge for true product development costs.

BENEFIT #3

USER-FRIENDLY

The WeldCloud-enabled machines only require WiFi to connect to the cloud. The WeldCloud application is as easy to install as Office 365, easy to learn and is accessible from any web-enabled device. Deploying WeldCloud is not a technical issue at all — the key to success requires finding the right people as the bridge between WeldCloud and the operators.

At Särkinen, that person is Building Coordinator and Foreman Tony Saarinen. He was a welder at the company for 15 years and works with computers as a hobby.

"Tony has the fire within to try new things and challenge others around him. The operators respect him because they know he understands issues from their perspective,” says Särkinen.

BENEFIT #4

READY FOR ROBOTICS

Having reached the maximum arc-on time for manual welding, Särkinen is now working with ESAB to install robotic welding systems and processes. A robotic system will increase arc-on time up to 80 percent and increase Särkinen’s ability to compete with lower cost countries.

In addition, because of the trust developed with the Digital Solutions team, ESAB has now earned Särkinen’s filler metal business.